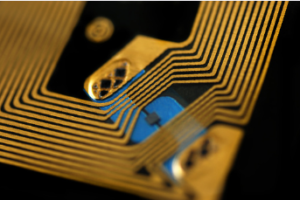

RFID (Radio Frequency Identification) is an identification and tracking system that utilises radio waves to identify and locate items. It can be used for monitoring everything from tools, equipment, and pallets of goods to people and vehicles.

Automated asset tracking with RFID offers numerous advantages for your business. These include real-time visibility, increased security, and improved inventory management.

Real-time Visibility

Are you searching for a way to keep your inventory and assets updated in real time? RFID asset tracking can provide numerous advantages that could save you money in the long run by eliminating manual entry.

Are you searching for a way to keep your inventory and assets updated in real time? RFID asset tracking can provide numerous advantages that could save you money in the long run by eliminating manual entry.

If your company is setting up an asset management program, then a system that can track the location and status of all your assets at any given time is essential. Maintaining records on high-value items helps guarantee they are in their proper places at the correct times; however, pinpointing their exact location within organisation premises may prove challenging.

RFID allows you to monitor all your high-value assets in real-time, regardless of location. This technology can monitor various assets such as trucks, forklifts and other machinery.

RFID asset tracking offers several key advantages, notably instant updates when an asset leaves a facility and arrives at its new destination. It helps eliminate needless shipping delays and boosts customer satisfaction levels.

RFID allows you to monitor the condition of an asset as it moves around your facility or through your supply chain. It helps determine if any damages or repairs are needed on the item.

Another advantage of RFID asset tracking is that it helps you keep tabs on inventory in your warehouse or distribution centre. You can monitor everything from how many items are in stock to how many have been delivered and shipped.

In the past, managing inventory required a lot of manual entry. But thanks to real-time asset tracking technology, you can now monitor every item in your warehouse or distribution centre with just a few clicks.

If you run a business, the success of your venture depends on the quality of products and services you provide to customers. Don’t risk missing any orders due to technical problems in your supply chain – real-time visibility is the only way to guarantee prompt deliveries.

Increased Security

RFID asset tracking enables businesses to monitor the location and usage of their assets in real-time via radio waves, with data processed and stored on a computer system. It provides companies with accurate, up-to-date data about their support, making monitoring maintenance cycles and inventory review more straightforward.

Passive RFID tags can be programmed with various data types, including a unique identifier that helps track assets. Furthermore, they contain memory chips that store additional data.

Active RFID tags, on the other hand, tend to be more costly than their passive counterparts but can be programmed with features like real-time tracking. Plus, they have a power source that enables them to transmit signals over longer distances than passive tags – ideal for tracking high-value items over long distances and outdoors – an invaluable benefit for businesses that must keep track of many assets.

RFID asset tracking provides invaluable data that can be utilised to enhance efficiency throughout the tracked items’ lifecycle. As a result, businesses save both time and money through this method while ensuring employees always have access to the correct equipment.

Improved Inventory Management

Maintaining assets, particularly equipment and tools that may be hard to locate, is essential for almost any company. Without this capacity, delays or interruptions in production can occur; other issues include lost or misplaced items, missed deadlines and customer commitments, and wasted labour.

Assets and equipment can be tracked using serial numbers and spreadsheets or barcode labels. However, both methods take a considerable amount of time, as well as extensive manual labour.

Another solution is RFID technology. This innovative system utilises radio waves to track and identify tags attached to assets and transmit data to a reader. It lets users view and track items in real time, enabling them to complete inventory tasks that typically take days or weeks.

Companies can enhance their production processes by tracking product movement. Doing so helps them eliminate bottlenecks and accelerate delivery times for finished goods.

RFID can also enhance customer service by providing accurate status information about an item. This data helps customers avoid wasting time and money by purchasing the wrong product or waiting too long for a replacement.